Versione in italiano disponibile qui.

What is Open Mask Sicily?

Open Mask Sicily is a collective effort of the non-profit association FabLab Messina to deal with the emergency of COVID-19.

Our goal is to offer material support to Italian hospitals, providing them, free of charge, with artisan protection devices. Our devices can be used temporarily during the pandemic emergency, to address the shortage of industrial-made equipment. Despite what our name suggests, we are not only limiting ourselves to donating masks, we have also contributed to the production of ventilator adapters.

Why FabLab Messina?

FabLabs are workshops of digital crafts, that is, places where it is possible to experience firsthand the conception, design and realization of objects through the use of the most modern technologies. The philosophy of open source and the sharing of information and resources are at the basis of any FabLab, and of course of our FabLab located in Messina, Sicily. We strongly believe in the potential of shared and collaborative development, both in presence and remotely, and in the in-house production of designed objects. We make use of several digital manufacturing machinery made available to members of the FabLab Messina (3D printers, CNC cutters, laser cutting machines, etc.). The ultimate goal of our association is to share our projects online, publishing them using licenses that encourage and protect the right to their free dissemination.

Our Initiatives

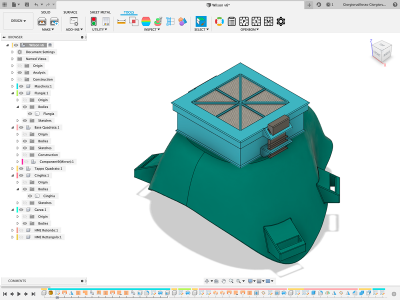

The FabLab Messina team has contributed to the development of different prototypes of masks that can be reused after sanitization. Our prototypes have gradually improved their ergonomics and mechanical characteristics. During this design process, the use of 3D printing – especially during the prototyping phase – and the ability of various FablLab’s members in the use of design software have been of fundamental importance. Both skills were often acquired by our members right inside the FabLab Messina. This project is a clear example of how the dissemination of tools and knowledge is not only fundamental for the growth of a community, but above all instrumental to the satisfaction of collective needs as, in this case, the availability of health devices.

Our Actions:

Makers call

Through a series public calls, our Association has promoted two initiatives both of which aim to create a large number of mechanical adapters for the lung ventilators used in intensive care units.

The concept is simple but the objective is ambitious. Through the use of social networks, we want to involve the largest number possible of makers, i.e. the assiduous users of digital manufacturing technologies (such as 3D printers). This way, we aim at producing as quickly as possible the devices requested by health care institutions.

The first initiative consisted of a collective call for 3D printing aimed at makers throughout Italy for the construction of 50 “Charlotte” adapters. These adapters, designed by Isinnova, allow the conversion of the snorkeling masks produced by Decathlon into masks for artificial ventilation of patients suffering from respiratory insufficiency.

The second call aimed at 3D printing 300 “Y” splitters, i.e. devices that allow two patients to breathe with a single pulmonary ventilator.

The participation to the calls has been a great success: an army of makers (almost 100 in total) has enthusiastically offered to contribute to the production, thus demonstrating a great spirit of solidarity and desire to do. In order to coordinate all the contributors, we quickly built an online platform to host the files needed for the printing. This platform, and the participation of Air Factories, made it possible to provide in just 48 hours the University Hospital G. Martino of Messina and the Department of Health of Sicily with ventilator adapters that could be used in the unfortunate event of an increase in viral spread.

The Wilson Mask

The masks have become the symbol of the health emergency we are experiencing. They were the first health devices to become scarce and for the first time in our history, we have begun to consider them not only useful but necessary. Our first action was therefore to create masks for personal use.

In this story, there are many protagonists who, thanks to the use of good practices of sharing and collaboration, have committed themselves so that their knowledge and skills could be put to the community service in the most efficient way possible.

It all starts with our associate Giovanni who, in the first days of emergency, decided to research online for a 3D printable template model. He identified one (Air Mask by grennet www.thingiverse.com/thing:4217534) which was released, thanks to the author’s good practice, with an open license. After printing the first pieces, Giovanni offered, through his Facebook profile, to print it for free for his friends. The “Giuseppe Fogliani” hospital in Milazzo (ME), Sicily, became aware of this opportunity and, by contacting Giovanni, asked to have these masks also for its hospital staff. At this point Giovanni got in touch with our FabLab and the Open Mask Sicily project was born.

Involving the FabLab meant involving a variety of professionals who, in this case, proceeded to analyze the original project, to highlight its critical issues and, in collaboration with doctors and experts of the sector, to make the appropriate fundamental improvements to enhance the effectiveness of the mask.

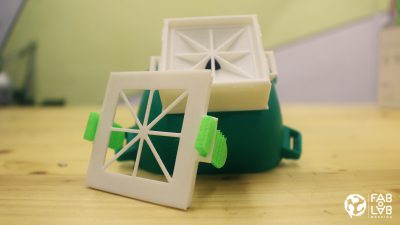

One of the first challenge we identified was the use of 3D printing for production. The additive production technology of 3D printing allows the construction of an object through the layered deposition of material. As it is possible to imagine, with this printing process, it is not feasible to guarantee that absence of micro gaps between the layers of deposited material. Those gaps could allow the passage of air and, therefore, of dangerous pathogens. 3D printing remains however very useful as it allows us to make prototypes in a very short time and therefore to be able to quickly iterate the testing of every new modification.

- 45°

- Fronte

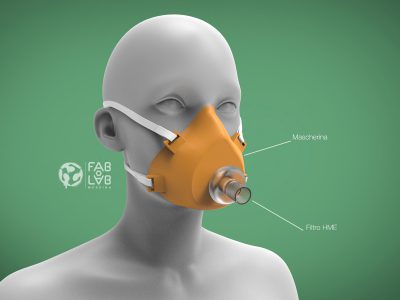

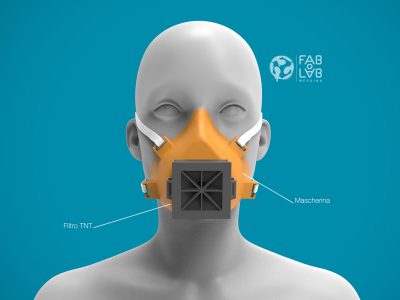

The continuous discussion with health workers has opened the way to new solutions that had not been originally planned. In addition to the non-woven fabric filter box – the solution originally implemented – we also considered the use of Heat and Moisture Exchanger (HME) filters. Those filters are reliable and long-lasting and are already available to healthcare facilities.

Our mask, recently renamed Wilson Mask, is freely available on Thingiverse and can be downloaded and made by anyone. Being a remix of a pre-existing project, the release and use license remains the same: we use the Creative Commons CC BY-NC-SA 4.0.

This project has reach an important milestone: the first examples of Wilson Mask have been produced with the final production technique of injection molding. The material used is Santoprene™, a non-hygroscopic vulcanized thermoplastic polymer with a rubbery consistency which has been already used in the medical and health care sector.

The first 20 specimens have already been delivered to the “Giuseppe Fogliani” hospital in Milazzo, Sicily in order to carry out the necessary experiments. The result of the experimentation will allow us to continue improving the design and finally to mass produce the mask.

What’s next?

We are currently working on obtaining a certification for the use of the Wilson Mask. If this milestone is reached, Wilson Mask would be the first certified open mask, freely reproducible by anyone.

DISCLAIMER:

It should be noted that all these illustrated so far are not medical-surgical devices, but Persona Protective Equipment (PPE) devices made to make up for the current supply shortages. These devices do not claim to comply with current regulations and certainly their quality is not comparable to industrial ones. These devices, however, serve to buffer a contingent need during this emergency. Each healthcare professional and each institution, therefore, will evaluate ways, times and functions to be given to the devices, as they are the expert on the subject.

CHow to support us:

Do you like the initiative and want to support the activities of our association? DONATE US!

Talking about us:

March 18, 2020 – Article on www.oggimilazzo.it

March 15, 2020 – Article by Cristina Saja on 24live.it

March 26, 2020 – Article by Dalila Ferreri on www.agrigentooggi.it

March 26, 2020 – Report by Riccardo Trombetta aired on Striscia la Notizia, national TV

March 29, 2020 – Article on La Sicilia

April 2, 2020 – Report by Marcella Ruggeri aired during the RTP channel broadcaster’s news (minute 16:10)

April 7, 2020 – Article by Alessandra Mammoliti on www.normanno.com

April 10, 2020 2020 – Article by Enzo Bon on www.ytali.com

April 17, 2020 2020 – Article by Santi Cautela on www.iltirrenico.it